What is a Bellows or Air Spring

Air suspensions, usually installed in all axles of trucks and cargo vehicles, including certain types of buses, tractors or semi-trailers, receive its name from one of its key components, namely the bellows.

The bellows is a pneumatic device that is manufactured to mimic a bag filled with gas, usually air, and which acts as a spring, reducing vibrations and providing better stability to the unit. Accordingly, it allows a safer and smoother driving to the vehicle operator regardless of the load carried.

The types of bellows are as follows:

1. Membrane

Rubber The upper and lower metal parts are located on the chassis and their replacement is not usually necessary.

2. Diapress and sets including connecting and fixing parts.

Easy to install

3. Torpress

Although it has a lower height, it can feature a relatively long run.

4. Seat and cabin bellows.

Bellows can be manufactured with the following materials:

• Natural rubber (single, double or triple bellows) (50%)

• Nitrile rubber (NBR) (25%)

• Styrene Butadiene rubber (SBR) (25%)

• Steel

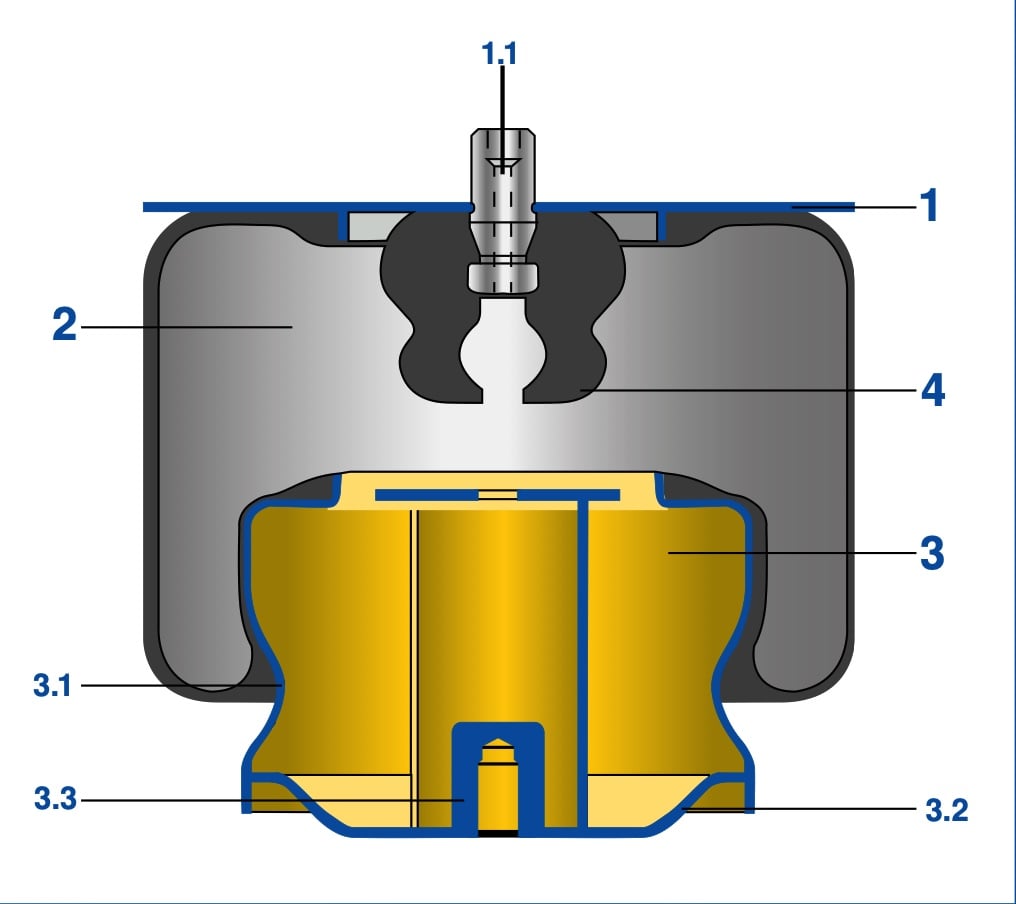

Example of bellows components (Bellows with conical seals on both sides)

1. Cone plate

1.1 Fixing bolts with pneumatic connection

2. Pneumatic bellows

3. Uncoiler piston

3.1 Piston skirt

3.2 Base plate

3.3 Internal fixing

4. Retainer

Main advantages of the air suspension for cargo vehicles

• More convenient load handling for tractors due to the simple trailer coupling and uncoupling solution.

• Greater reliability and safety when transporting fragile products thanks to the even absorption of road irregularities and lower vibrations in the vehicle's cargo area while driving.

• Transportation of higher cargo volumes, keeping them at a constant distance from the road at all times.

• Increased braking control and thus safety depending on the load carried.

• Its operation and implementation guarantee a longer road life because it dampens the impact of the truck’s weight and that of its cargo on the road.